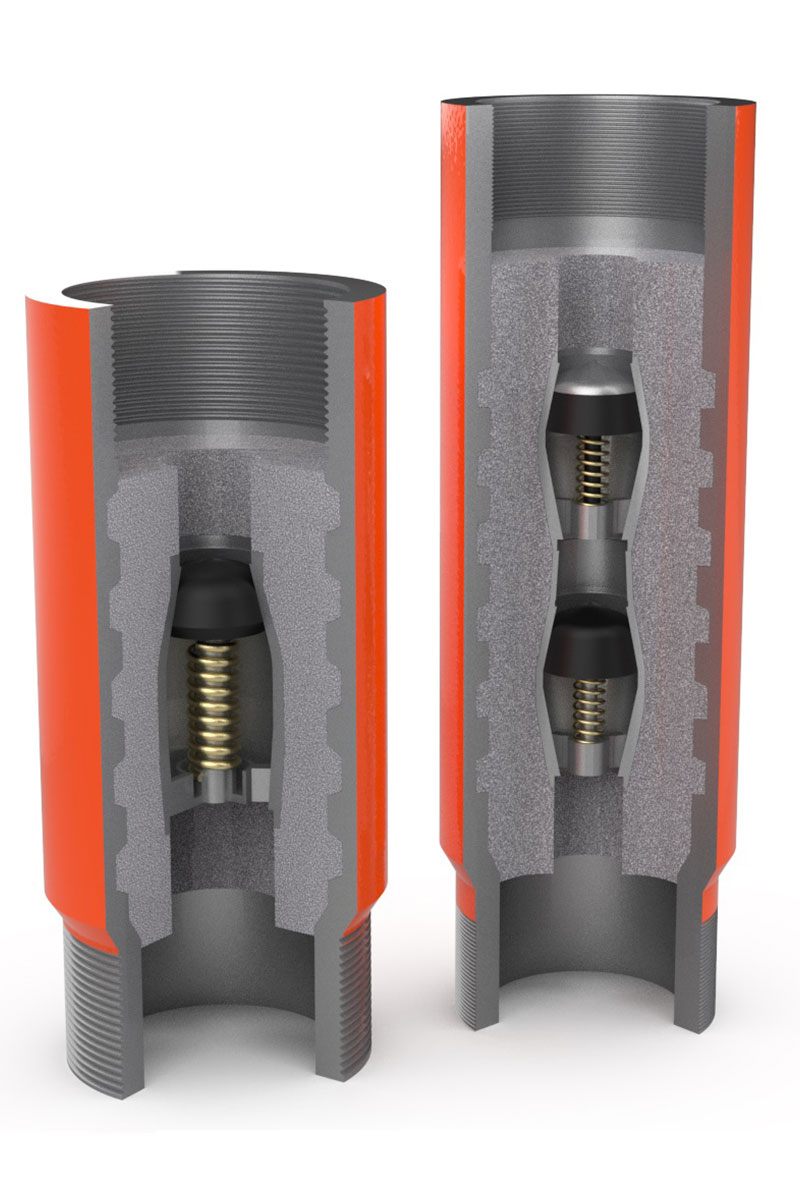

Conventional Float Collar Single/Double Valve

(COT-SVFC-102/COT-DVFC-102)

Crimson – Float collars designed are made from seamless casing grade steel and supplied with an internal (non-returnable) valve which is tested and rated in compliance with API RP 10F standards. Float Collars are manufactured with the latest CNC machines. The check-valve assembly fixed within the float collar prevents the flow back of the cement slurry when pumping is stopped. Without Floating Equipment, the cement slurry placed in the annulus could U-tube, or reverse flow back into the casing. The greater density of cement slurries than the displacement mud inside the casing causes the U-tube effect.

This design ensures positive sealing in vertical, horizontal, and deviational wells. The material used for float equipment is seamless casing-grade steel. Float equipment can be supplied in all grades of steel like K-55, L-80, N-80, C-95, T-95, and P110.

Available in single and double valves with sizes 4 ½” to 20” and any special sizes can be available on request.