In an industry as dynamic as upstream oil & gas, maintaining the integrity of a well over time hinges, in part, on the quality of a cementing operation. Crimson Oil Tools concentrates on the successful execution of operations by engineering and fabricating high quality precision cementing accessories. This entry will discuss the important role of plug cementing, the bow spring centralizer, and sound design principles in achieving dependable zonal isolation and support of casing in oilfield cementing.

Understanding Plug Cementing and Its Importance

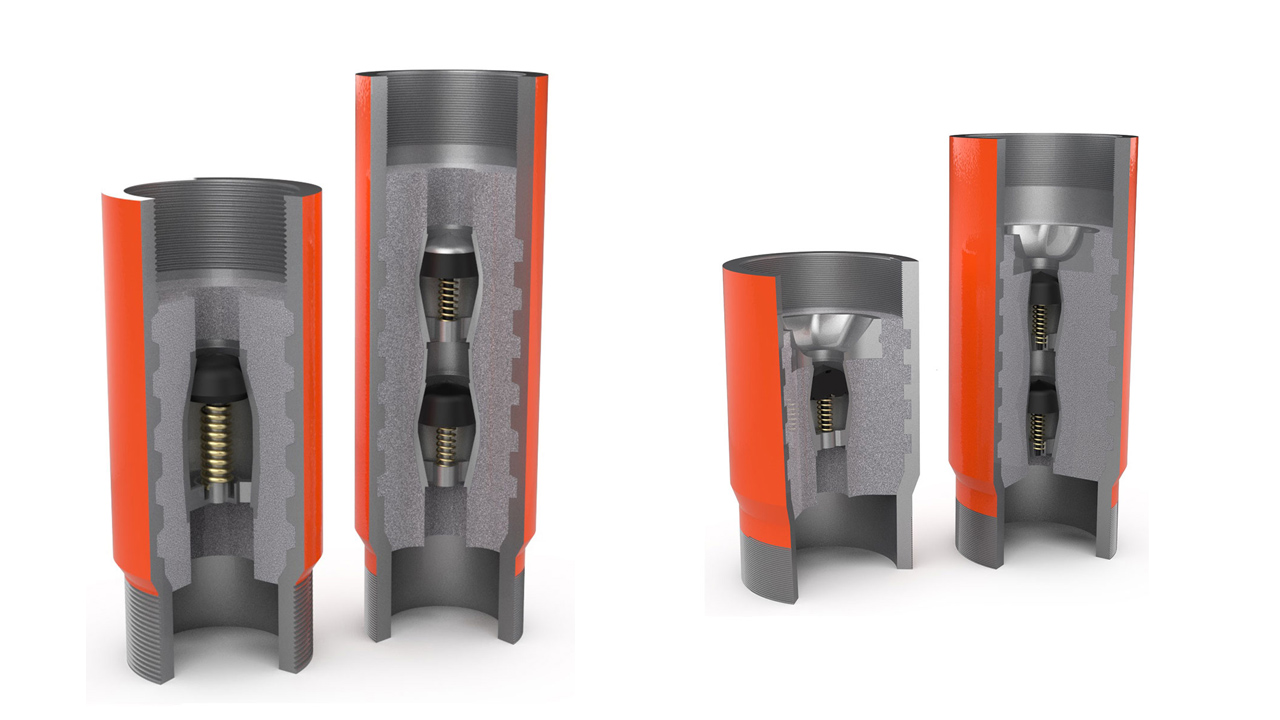

Plug cementing is a method used in cementing operations where special devices known as plugs are used to control the interface between cement slurry and the drilling fluid. The method involves the use of a bottom plug and a top plug. The bottom plug is sent first to isolate the drilling fluid and after it has been landed the cement slurry is pumped. The top plug is then sent to wipe the casing as the cement is pushed downward until it reaches the bottom plug or landed collar. This method provides:

• Contamination prevention between fluids.

• Clean interface provision.

• Pressure indication upon landing.

• Improved displacement of mud by cement.

As noted in the oilfield glossary, it is the cementing plugs that preserve expected slurry behavior and prevent the mixing of disparate fluids.

Crimson Oil Tools offers many types of cementing plugs including conventional, rotating, non-rotating, combination and pneumatic. All of which, have been designed with the right dimensions and solid materials to meet the requirements of pressure and temperature.

Centralizer Bow Spring: Making Sure Centralization Stays Muscled Downhole

One of the components that impact the quality of the cementing job is the degree to which the casing is centralized in the wellbore. For such situations, the centralizer bow springs become useful. This centralizer type holds springs that push outward, subsequently holding the casing centered and within specific distance standoffs from the borehole wall.

Some of the benefits associated with the use of centralizer bow springs are:

• All but absolute restoring force : The springs come back to their original positions in response to movements of the casing and positions it back to the central line

• Minimal initial drag : Spring configurations culminate in passive run-in force reductions

• Variety of uses : Springs can be used efficiently in vertical, deviated, and, to a lesser extent, horizontal well placements

• More effective displacement, minimizing the incidence of channeling

There are bow spring centralizers and they come in 10D API specifications. The bow spring centralizers come in several styles including slip-on and hinged options.

At Crimson Oil Tools, Customer bow spring centralizers (hinged, welded, slip-on designs) are tailored to specific casing sizes and advancements in design technologies.

Integration in Oilfield Cementing Programs

A strong oilfield cementing program can be achieved by combining plug cementing with an effective centralization technique. Here’s how this can be achieved in practice:

1. Casing Run — A casing string is lowered, and centralizers (including bow spring centralizers) are attached at specified intervals.

2. Plug Cementing Start — The bottom plug is deployed, cementing ahead of the drilling fluid.

3. Cement Slurry Pumping — Cement is pumped to fill the annulus, displacing mud and achieving zonal isolation.

4. Top Plug Launch — The top plug wipes the casing and a pressure spike signals that it has landed.

5. Curing & Evaluation — Cement is allowed to cure and then bond logs are run to check for cement quality and coverage.

Utilization of bow spring centralizers guarantees that the casing is properly centered which in turn improves the consistency of the encapsulating cement sheath. Well centralization helps in diminishing channelling and in voids which leads to enhanced performance in oilfield cementing.

Reasons to Choose Crimson Oil Tools for Your Cementing Accessories

• Complete Cementing Portfolio — From plug cementing accessories to centralizers and bow spring centralizers with related equipment, we offer a full line of tools.

• Custom Design & Precision — We customize sizes, materials, and configurations according to your well conditions.

• Quality & Certification — We maintain stringent industry standards and quality control throughout our manufacturing processes.

• Global Reach, Local Support — With headquarters in India, we serve clients in various geographical areas and focus on prompt delivery and collaborative assistance.